Dieter Finna (Click here for a German version)

Higher prepress costs in addition to multi-step production processes often stand in the way of the application of finishing effects. Packaging designers in particular would like to use them more frequently to enhance the appeal of labels and packaging. New digital modules from Gallus are bringing momentum to this gridlocked situation. Integrated inline in the printing process, they implement promotional design effects economically in one operation and thus keep production costs low.

Numerous effects are available for digital print finishing of labels and packaging. These include high-gloss surfaces, matt-gloss effects with high contrast, a wide range of tactile design effects and the use of digital metal relief effects with cold foil. The pre-printing of opaque white as a basis for brilliant colour effects and the printing of opaque texts on transparent films are also among the digital finishing effects used. These effects offer an alternative to effects conventionally created in screen or flexographic printing and impress in practice through their radiance and cost-effective implementation options.

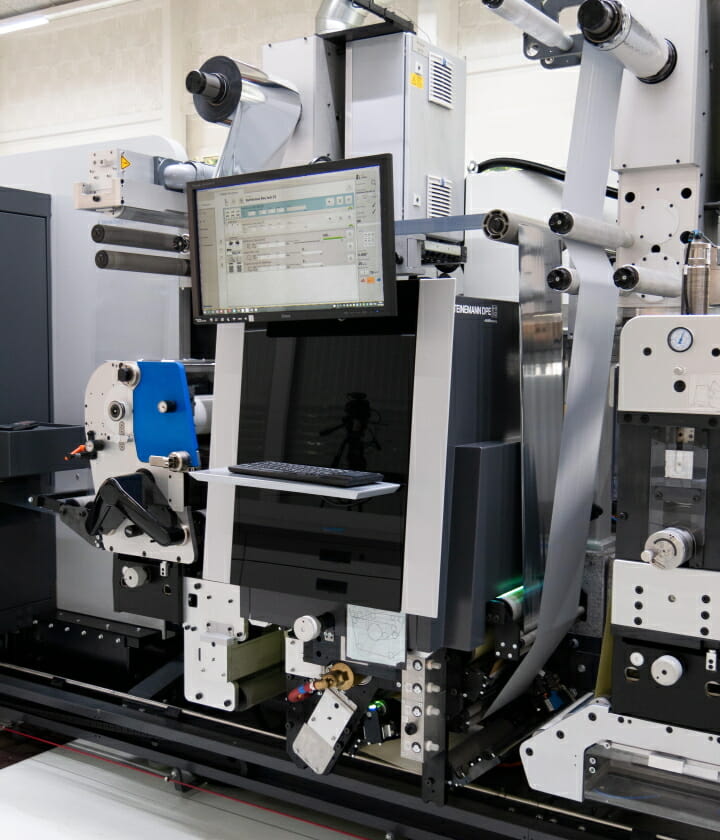

In general, Gallus offers two different modules: the Digital Embellishment Unit (DEU) and the Digital Printbar »White Edition«. The two modules differ in terms of their finishing options and positioning options within a printing system.

Digital Embellishment Unit (DEU)

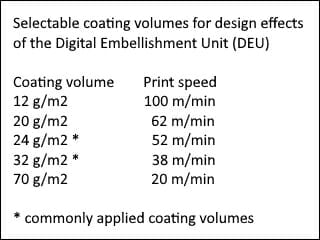

In a Gallus Labelfire, the module enables embellishment and printing in a single operation in a completely digital workflow and is installed directly behind digital or conventional printing units. »The DEU implements both matt and glossy spot coatings through to tactile relief effects with a coating volume of up to 100 g/m². What is extraordinary about the DEU is that it implements three different coating effects in one pass and can thus replace up to three conventional printing stations«, says Thomas Schweizer, Head of Product Management at Gallus Ferd. Rüesch AG, explaining the advantages of the Digital Embellishment Unit. The maximum applied coating volume determines the achievable printing speed. A coating volume of up to 24 g/m² is possible at full machine speed. The machine speed is reduced with higher coating volumes.

Metallic effects can also be achieved in conjunction with a cold foil unit. The coating, which also serves as an adhesive for the cold foil for this application, is applied digitally. If the amount of coating applied is correspondingly high, a metal relief effect is created through which digital metallic doming – as a digital finishing step – is possible. This universal UV-based coating was developed by Actega Schmid Rhyner specifically for use in the Digital Embellishment Unit.

Metallic effects can also be achieved in conjunction with a cold foil unit. The coating, which also serves as an adhesive for the cold foil for this application, is applied digitally. If the amount of coating applied is correspondingly high, a metal relief effect is created through which digital metallic doming – as a digital finishing step – is possible. This universal UV-based coating was developed by Actega Schmid Rhyner specifically for use in the Digital Embellishment Unit.

»What is extraordinary about the DEU is that it implements three different coating effects in one pass and can thus replace up to three conventional printing stations«, says Thomas Schweizer, Head of Product Management at Gallus Ferd. Rüesch AG, explaining the advantages of the Digital Embellishment Unit.

Digital Printbar »White Edition«

The Digital Printbar »White Edition« was first presented at Labelexpo Europe 2019 in Brussels/B. It is used for the digital insetting of highly opaque UV white with a layer thickness of ≤ 10 µm. »With this ink transfer it is the digital alternative to a conventional screen printing unit. Compared to conventional production, however, it offers greater flexibility as no printing plates are required and can be used up to a printing width of 430 mm (17″)«, says Thomas Schweizer, describing the new module. The Digital Printbar can be moved on a rail system above the primary level of a conventional press and can thus be used for white pre-print and/or white imprinting, before or after the printing units of a conventional press system. In future the Digital Printbar will also be available for applying UV coatings for matt/gloss effects and tactile applications.

Economic efficiency of digital printing units

With all the technical possibilities offered by digital modules, the economic efficiency of their use is dependent on the unit costs of the orders produced on them, i.e. whether an investment in such a system is worthwhile for the user. For calculation purposes, it can be assumed that the investment costs in a printing system with a digital module will increase by approx. 250,000 EUR.

How cost-effectively the orders can be produced on it can be determined on the basis of a cost comparison in which the production variants with and without the use of digital modules are compared. The following comparisons of production variants show up to which print runs machine systems with digital modules are more cost-effective. The intersection of the curves indicates the respective marginal costs, i.e. from what print run a conventional production of the orders is the more cost-effective variant.

Comparison of variants of the print image »Bathlicious« with the DEU

In both versions of the bath salt folding carton »Bathlicious«, the coloured design elements are printed on the Labelfire 340 using 7-color UV inkjet printing. A matt film is then laminated on, the contrast of which makes the gloss effects particularly effective.

The first variant is produced completely digitally, with the tactile and optical effects achieved by applying a 32 g/m² varnish in the DEU. In the second variant, the print finishing is carried out by screen printing. For this, the production of a screen must be calculated in the preparation of the order.

»The cost comparison of the ›Bathlicious‹ variants using a TCO calculator (Total Cost of Ownership) shows that the Gallus Labelfire 340 with Digital Embellishment Unit is the more cost-effective option in print runs from 1’000 to 11’500 labels (123–1’415 linear meters)«, explains Uwe Alexander, Area Sales Manager at Gallus Ferd. Rüesch AG, explaining the evaluation of the cost comparison. »An additional advantage of the digital variant is that a proof or a mock-up can be produced as edition 1, which means that a colour-binding sample is available for print approval before the edition is printed. From a print run of 11’750 labels (1’446 linear meters), production on the Labelfire 340 with conventional coating application by screen printing is the more cost-effective option.«

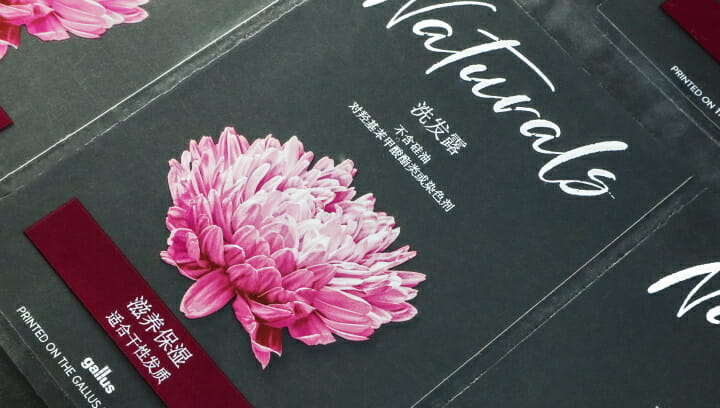

Variant comparison print image »Naturals« with the Digital Printbar

The Digital Printbar is integrated into a conventional printing press such as the Labelmaster for print finishing. The »Naturals« print example presented here is a label with four language variants that are printed as an imprint in the dark red text field or directly on the transparent film. The white areas under the flower motif and the red text field as well as the »Naturals« lettering are each presented in screen printing. The remaining design elements are printed in five colours (process colours + special red) in flexographic printing with three multiple copies side by side. The white Chinese characters, the Gallus logo and the words »Printed on Gallus Labelmaster« are printed as an alternate form in screen or digital printing.

The design variants differ in that in the first variant, the languages are printed with the Digital Printbar. The texts are digitally imprinted with UV white in a layer thickness of ≥ 4 µm. The UV ink is cured in a dryer in a conventional Labelmaster printing unit. Thanks to the digital imprint of the languages, this variant saves set-up times and the production of four screens, as required for the second, third and fourth language variants with screen printing units.

»The cost comparison shows«, explains Uwe Alexander, »that the Labelmaster 440 variant with integrated Digital Printbar is the more cost-effective variant regardless of the print run.G On the one hand, this is due to the shorter setup time of 53 minutes thanks to the integration of the module. 45 minutes are needed to set up the Labelmaster and 4 x 2 minutes to set up the language variants with the Digital Pintbar. With conventional production, 65 minutes (45 + 4 x 5 minutes) are required to set up the Labelmaster with screen printing unit. The decisive factor for the cost advantage with the Digital Printbar is the saving of set-up waste, since only 160 running meters (120 + 4 x 10 running meters) of waste are required when printing the language variants, compared to 480 running meters (120 x 4 running meters) for the variant with screen printing unit.

Summary

The two cost comparisons show that digital modules significantly reduce the unit costs of printing and finishing. Especially for short runs, designs with inline print finishing can be offered at very attractive prices. The cost per 1’000 units is well below that of production variants with conventional work steps. In the comparisons shown here, depending on the application, this can extend to run lengths that are customary in the market, especially when language, text or design variants come into play.

So the arguments of much higher pre-press costs or multi-stage production processes no longer stand in the way of digital print finishing. Inline production with digital modules has therefore made the implementation of finishing effects amazingly simple.

The other examples of vodka, champagne and wine labels illustrate the advertising effects available. They show a small excerpt of the appeal of designs with digital finishing and impressively demonstrate the creative freedom that digital modules offer for attractive packaging and label design. For the label and packaging market, the use of digital modules opens up a cost-effective process route to labels and packaging with increased advertising effectiveness.