Dieter Finna (Click here for the German version)

Tony Snyder’s key note »This Changes Everything« was a real highlight of the Digital Print for Packaging conference 2018 in Berlin/D. The vision of a »smoke-free future« not only continues to radically change the product portfolio of Philip Morris International (PMI) in terms of alternative products to traditional smoking. It also places stringent demands on the supply chain in terms of flexibility, agility and speed to market. Because these are the strengths of digital printing, PMI decided to invest in a hybrid digital printing line from Gallus at its Swiss development facility in Neuchâtel/CH. The key question for Philip Morris is: how far can they develop a digital end-to-end production line for all the smaller batch sizes within a production-related environment?

Designing A Smoke Free Future

With its strategic decision to replace conventional cigarettes with less harmful products, Philip Morris finds itself in a transformational phase marked as journey towards a smoke-free future (www.pmi.com/who-we-are/designing-a-smoke-free-future).

Tony Snyder, responsible for Product Portfolio Management and Deployment at Philip Morris says the company is working on reducing approximately 40 billion packs of cigarettes to zero. In the transformation of the business model, the company is now confronted with new competitors and customer segments. And PMI is certain that in the next 12 months, there will be more changes for the company than there was in the last 10 years.

From catalogue to finished good in 7 days

Today, product launches or product modifications of conventional products involving two SKUs (Stock Keeping Units) take approximately 4 months to get to market. In case of worldwide launch, the time to market increases up to 2 years. Such a long introduction time the company can’t afford anymore. With increasing number of items and SKU’s, changing market and competitive environment, the solution is not to get just a little faster. Disrupting speed to market requires a fundamental change in the complete supply chain.

It is clear that such a radical change is only possible with new technologies which allow to shift production schedules on the fly and quickly adapt production to consumer demand. The challenge is to identify beforehand which products consumers will like the most and which products need to be in the market tomorrow. In response to the need of accelerating speed to market, PMI has established the goal of seven days from catalogue to finished good production.

Speed and agility, keys to greater responsiveness and accuracy

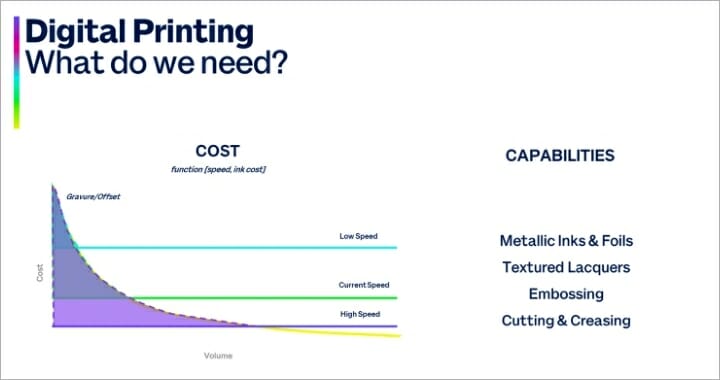

Digital printing already offers significant flexibility, agility and quick changes in label printing. The question is why digital has not achieved this in folding carton printing yet? The answer? Digital printing is missing, and that’s nothing new, two things – capability and a competitive cost structure.

In the conventional printing processes in gravure and offset printing, very short runs are synonymous for high costs as pre-press and set up costs are shared by a small volume. For large volumes, conventional processes are very effective and economical. Here a more competitive positioning of digital printing is needed. A few years ago, digital printing still had a low speed and therefore a high cost structure, which meant that digital printing at PMI could only be used for special editions or for individual local test markets. For PMI, runs of 1 million packs are still considered short runs.

In recent years, however, digital printing has continued to evolve, reaching a point in terms of print speed where job orders of around 5 million blanks can be produced competitively today.

»Today, order sizes of about 5 million blanks can be produced competitively in digital printing.«

Gravure printing is so inexpensive today as it handles high volumes. But the industry is subject to the general development trend towards smaller editions. Capital tie-up and stocks that block or slow down the supply chain are no longer desirable. As a result, the run lengths have become smaller and smaller. And, as digital printing speeds continues to increase and costs go down, more and more of the PMI product portfolio could be considered for digital printing in the future.

PMI opted for a hybrid solution from Gallus

What digital printing is missing today are solutions for metallic inks and other digital embellishing, which make packaging in an exclusive market something special. It is not enough just to transfer the color digitally while the embellishing is done using either hybrid technology or a separate production step. In order to meet the market’s demand for the greatest possible flexibility, agility and speed to market, the complete workflow must be digital.

PMI decided to explore and stress test the possibilities of digital printing itself. The modularity of the Gallus Labelfire was the decisive factor for choosing this technology with which the hybrid components for a »Boardfire« line could be specifically configured.

It is equipped with 8 digital color printing units for printing in the extended color gamut, 6 flexo units including the option to apply cold foil. Today, the machine is much different from the original Labelfire design. Last December, a laser equipment for cutting and creasing was installed, so bit by bit the production line is being digitized.

State of Knowledge and how goes from here

A clear awareness for PMI today is that digital technology will only bring the anticipated value if it is close to manufacturing. As an end-to-end solution, all production steps must be digital and all the necessary printing, embellishing and finishing steps must be carried out in one go.

»PMI decided for a Gallus Labelfire because of its modularity.«

The line has already been utilised for the digital color standard settings of more than 50 products. Designs of over 200 SKU’s have been carried out on it. In addition, stress tests were carried out under the conditions that the machine is in a factory and not a development environment. So far, packaging for 100 million cigarettes has been produced there. This was the first step in confirming that the technology works. Now PMI is finding out if it is an industry-ready solution that covers the full range and whether it will actually enables finished good production within 7 days.

PMI has decided to install a digital line in the production environment of a factory in 2019 to gain insight into how the technology can be integrated into the production and planning systems. As a result, who knows, a digital printing line will be available at each production site in the future.

Philip Morris International

In 1847, Mr. Philip Morris opened a shop on London’s Bond Street. Today, Philip Morris is a leading international tobacco company with a diverse workforce of around 81,000 people. In 1924 Marlboro, which has become the company’s most famous brand, was introduced. In the 1950s, an internal operating division was launched to manufacture and market products around the world. The PMI operations center was transferred from Rye Brooks, NY (USA) to Lausanne, Switzerland in 2001 and in 2009 PMI unveiled its new research- and development facility in Neuchâtel (Switzerland) bringing together over 400 scientists, specialists, and staff in a new world-class facility dedicated to development of reduced–risk products. The company made a far-reaching decision, to build the future on smoke-free products and to replace cigarettes as soon as possible.